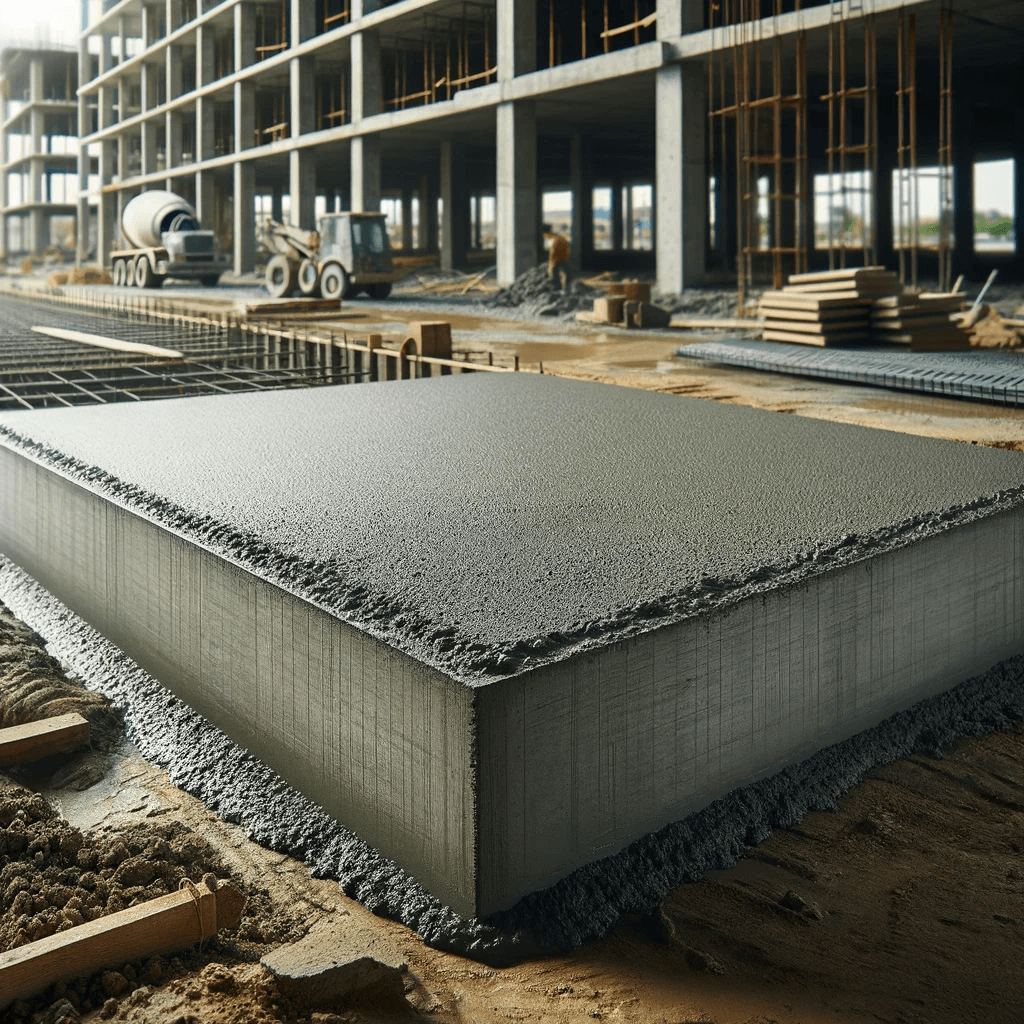

Cast-in-Place Concrete

Use this 3 part master specification template to specify cast-in-place concrete for use in site construction, foundations, floor slabs, building frames, mechanical pads, and other uses.

This section may be cross-referenced from other sections that require cast-in-place concrete.

Concrete for structural uses is often covered by general notes contained on structural drawings. Coordinate with such notes to prevent duplication and conflict.

Concrete formwork comes in many different materials and configurations to suit project requirements:

- Wood panels: Different plywood grades are available to provide specific finishes. Ranging from typical plain concrete for concealed surfaces to overlay types that provide smooth surfaces for exposed surfaces, including “architectural” concrete. Panels can be reused several times before they are discarded.

- Wood boards: Traditionally, concrete was formed with individual boards rather than panels. Now commonly referred to as “board-formed concrete,” this finish provides a more rustic, historic appearance. Boards can be reused several times before they are discarded.

- Metal: Prefabricated steel forms work well for repetitive forming where field cutting is not necessary. Forms can be reused almost without limit.

- Glass fiber: Similar to metal forms, these prefabricated forms work well for repetitive forms. Reuse is almost limitless.

- Spirally wound tubular forms: Often used for round columns, the resulting concrete can be concealed or left exposed.

- Carton forms: Used to provide a void space between the bottom of a foundation and expansive soils, these forms are left in place and eventually rot away.

Reinforcing steel comes in two types:

- Deformed bars provide an irregular surface that bonds with the concrete, preventing slippage. Bars can be bent to required shape and connected by wire tying or welding.

- Welded wire mesh uses wires placed in a rectangular pattern and welded at the intersections. This type of reinforcing is commonly used for concrete flatwork.

In climatic conditions where rusting of the reinforcing is anticipated, galvanized or epoxy-coated reinforcing can be used.

The simplest concrete mix includes Portland cement, aggregate, and water. Varying the amount of each ingredient results in changes to compressive strength, slump, and finishing characteristics. Additives also change the concrete’s characteristics.

Concrete must be protected from moisture loss until it obtains its final characteristics, a process called “curing”.

Curing is done using several methods:

- Curing compound: A chemical compound is applied to the concrete immediately after placement. This is typically used on slabs and flatwork.

- Curing paper: A special paper is placed over the concrete immediately after finishing.

- Wet curing: Concrete is kept moist by wetting with clean water.

Many other concrete finishes are available beyond what is included in this section, including:

Flatwork:

- Exposed aggregate: Specially selected small aggregate is placed in the concrete mix. After placement the surface is washed with clean water to remove the overlying cement matrix. Alternatively, aggregate may be “seeded” onto the wet concrete surface and embedded by rolling prior to concrete set.

- Surface retarded: A chemical compound that delays concrete set is applied to the concrete immediately after floating and troweling. After the lower concrete sets and the surface has achieved the desired look, the chemical compound is washed off.

- Salted: After the concrete is floated and troweled rock salt is broadcast over the surface and allowed to pit the surface to the desired look, then washed off.

- Sandblasted: Concrete is floated and troweled, then allowed to set. The surface is then sandblasted to a predetermined depth and exposure of aggregate.

- Patterned or stamped: After the concrete is floated and troweled a pattern is pressed into the surface her using mats or tools.

Vertical surfaces:

- Architectural: Special forms are utilized along with removable form ties placed in a regular pattern. Locations of ties and form joints are established on shop drawings.

- Sandblasted: Concrete is floated and troweled, then allowed to set. The surface is then sandblasted to a predetermined depth and exposure of aggregate.

- Form liner: Patterned sheets are placed on the interior side of exterior surfaces formwork prior to concrete placement.

To learn more about concrete, visit Wikipedia.

Related Specification Templates: